Rotating equipment, oscillating equipment and helical equipment all require bearings to allow for free rotation and to eliminate contact between moving and stationary parts. Seals are used to keep the lubricating fluids in while preventing ingress of the environment. As parts rotate at higher speeds and higher pressures and operate at higher temperatures, the need for our highly engineered seals becomes ever more important.

HYDRAULIC & FLUID SEALS

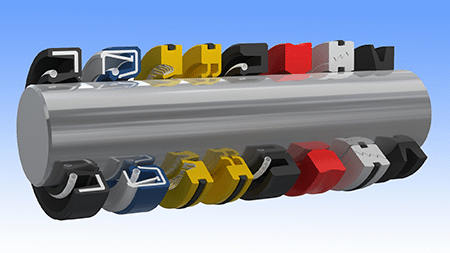

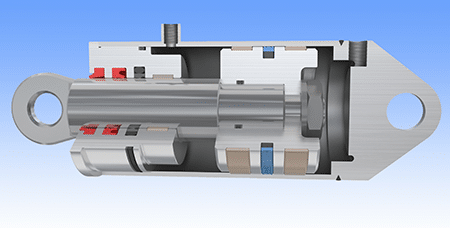

For sealing dynamic, linear and reciprocating motions

Hydraulic cylinders and other linear motion devices are sealed using a combination of seals and ancillary devices as shown above. Each of these items is subject to ever increasing pressures, temperatures and forces that shorten seal life. We utilize state-of-the-art designs and materials to extend seal service life in even the most arduous of conditions.

APPLICATION-SPECIFIC SEAL DESIGN

On many occasions, a standard seal is shoehorned into an application as the “closest fit.” We believe the seal should be designed around the application. Our engineering staff has been designing seals to meet the requirements of specific applications for the last 25 years and is uniquely qualified to understand your exact needs, ensuring that you get the right seal in the right material.

SPRING-ENERGIZED PTFE SEALS

Spring-energized PTFE seals are typically used in areas where elastomeric seals cannot meet the frictional, temperature, pressure, or chemical resistance requirements of the application. We use a variety of spring types and a vast array of advanced materials to create solutions to a wide range of sealing challenges.

PUMP SEALS

For over 20 years, we have been developing sophisticated solutions that aid pumps to operate more efficiently in evermore challenging conditions — lower friction, higher pressures, wider temperature ranges, faster speeds — all while pumping a wider range of fluids that are more corrosive, less stable and, in many cases, offer much less lubricating effect.

OILFIELD SEALS

The requirement for equipment that can operate more efficiently in ever more challenging conditions has led us to develop a growing family of oilfield-specific seals. Requirements for seals to operate at higher pressures and temperatures (HPHT), lower friction, faster speeds, and with more corrosive fluids, etc., has created the need for some very innovative sealing solutions.

FDA-COMPLIANT SEALS

We have many seals that were specifically developed to meet the unique challenges presented by the preparation, processing, and dispensing in the food and pharmaceutical industries. Our designs are suitable for CIP (Clean In Place), COP (Clean Out of Place), and SIP (Sterilization In Place).

Materials offered conform to FDA CFR 21 Code.